COLOURED

Coloured Movement Joints are bespoke for any hard flooring, natural stone and slate.

We specialise in colour matching our Movement Joints to the grout or the floor finish allowing you to create a stylish interior with a coherent finish. Our Joints are designed and manufactured to exceed the requirements of BS 5385. They form part of our wide range of trims and accessories for flooring.

We regularly produce Movement Joints in the most popular RAL coloured infills to minimise lead times as much as possible. Our Bespoke Movement Joints carry lead times of between one to three days depending on the quantity needed and production capabilities. We offer a next day carriage service to most UK destinations which means there is minimal interruption to your project.

If you can’t see a colour below that is suitable for your project, simply pick one from the RAL colour chart and we will make it for you.

THE BENEFITS

We can match to any tile or grout using the RAL colour chart.

Designed and Manufactured to exceed BS5385.

Our Joints can cope with heavy stresses.

Between the foundation and floor covering, preventing “tenting” and “popping”.

Prevents the conduction of noise from footfall and other bodies.

Epoxy infill to provide movement accommodation.

Resistant to puncture and has anti-bacterial properties.

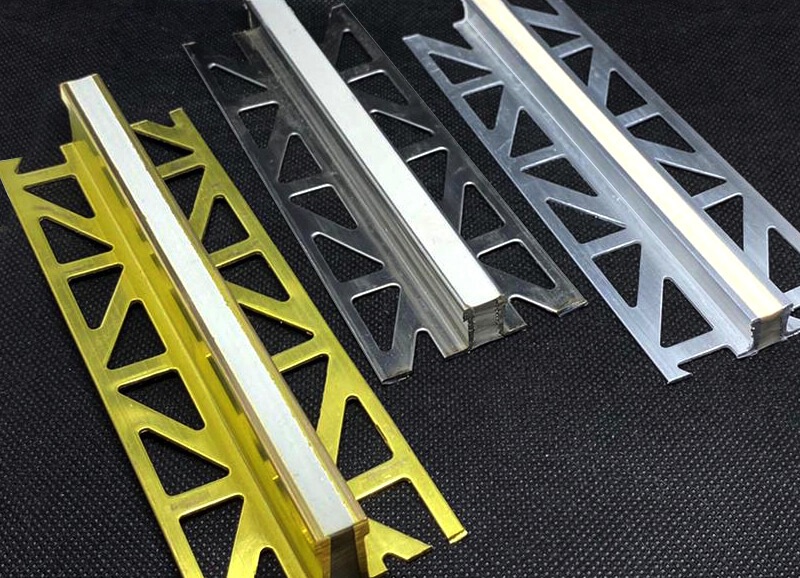

Available in Aluminium, Stainless Steel and Brass.

In order to select the right Movement Joint for your project the following criteria needs to be considered:

Car showrooms, supermarkets and retail premises are typical projects where aluminium based Movement Joints are used. They provide good movement accommodation and excellent tile edge protection.For commercial and industrial use where the weight over the joint is high such as areas where forklift trucks and loaded heavy pallet trucks operate, Stainless steel supported Movement Joints are a better choice. Stainless steel is also recommended in areas where chemicals are present such as swimming pools and food production units where an aggressive cleaning regime is required.Brass based Movement Joints whilst being strong and having a high resistance to chemical attack are less popular and are chosen more for their traditional or high quality appearance.

Every project has a design theme and a lot of time and effort is spent choosing the right type and colour for a floor covering. It is often an unwelcome design aesthetic to have a Movement Joint showing in a beautiful sweeping floor design but Movement Joints MUST be included to protect the floor.

Select the type of profile your floor needs based on weight and traffic.

Decide on the infill colour that best suits your tile surface ( or grout ). You can quote a RAL reference or send us a small piece of material for a colour match.

The result will be a Movement Joint that won’t clash or intrude on your design.

Minimum quantity – 1 x 2.5 metre length

Delivery time – Bespoke colours are normally 3 working days and Stock Colours next day to site

In order to determine where to place the profiles it is necessary to inspect the subfloor. Day joints in the screed or pre-existing compound joints will often be the deciding factor. Many of these existing joints are approximately 6 metres apart (British Standard guideline is a max of 10 metres) which can often cause problems with tile layouts leaving some awkward cuts. Please contact us to discuss this in more detail. Some subfloors are monolithic and have no subdivision. In these situations the Movement Joint position can be adjusted to best suit the aesthetic layout of the tiling following the 10 metres guide (see section on heated floors).

As a starting point use the pre-existing joints in the subfloor for your layout but don’t forget the perimeter requirements. A joint in the subfloor or a change in materials (such as concrete or screed to timber) is a scenario that requires a Movement Joint at that point. A kitchen extension or the addition of a sunroom are typical layouts where vertical movement occurs.

As sad Movement Joint fanatics we check out floors wherever we go. It’s always disappointing when we see a failed floor. We want people to be happy with the installation so that they use tiles again – hopefully with our products! The purpose of this section is to highlight what happens when basic rules are not followed. The most common causes of failure are completely avoidable. These are as follows:

All Movement Joints MUST be placed directly over each other throughout the floor structure. Consider that if the purpose of a Movement Joint is to absorb movement, placing it anywhere other than the movement site is not going to help. By bridging the area of movement with a rigid tile, of any material, it is going to crack at that point. For example, a fairly straight crack will appear in the tiling, usually about 10cms or less from where the Movement Joint is actually fitted.

It’s worth noting that straight cracks are usually caused by vertical movement in the subfloor. Where “lightning flash” cracks appear this is normally caused by horizontal movement within the subfloor. Tiling early onto unstable surfaces such as green screeds can also cause this problem. Sometimes indicated where tiles “tented” or “popped” under compression.

Specifiers

To avoid the above it might be necessary to cut tiles to achieve correct placement. Our colour matched profiles will minimise the aesthetic impact.

Fixers

Miss aligning Movement Joints may save time in the short term but is the time saving involved in cutting tiles worth your reputation?

Cracks can appear alongside perfectly placed movement joints. Typically these would be “half moon” in shape. This are due to a failure to ensure that the fixing flanges of the movement joint are fully embedded into the tile adhesive. All reputable suppliers of movement joints will stress the importance of this solid bedding. Not only is it needed to fully support the tiles at this vulnerable point but also to ensure that the extension and compressive forces within the floor are fully transferred through the supporting profiles to the flexible infill material.

A simple test for this fault is to take a £1.00 coin and use it to tap along the edges of the tiles alongside the movement joint. Where the tiles are solidly fixed the sound is dull. Over hollows in the bedding the sound will change to a sharper, clearer tapping. Invariably if the tiles are lifted for investigation this simple test has proved accurate.

Specifiers

Make sure that your fixing team are reminded that solid bedding is your absolute requirement.

Fixers

Fixers given the job of constructing movement joints must be competent and it must be understood that the rules regarding the open times of adhesives etc are followed. Planning and pre cutting of the tiles can avoid delays which cause bonding problems.

This problem is in two parts both of which can affect the longevity of the tiled installation.

Size- the depth of the movement joint must match that of the tile and adhesive bed. Ideally the top of the movement joint should be slightly below that of the tiles. (1 to 2mm maximum). Under no circumstances should the movement joint be proud of the surface. The movement joint should not be considered as a stepping stone for traffic. They are not designed accept these impacts and stress in isolation.

Typically the signs of an incorrect size would be – Too tall = impact damaged side supports. Too small = chipped tile edges.

Material - this is an example of over optimistic cost saving. Plastic Movement Joints have a very limited use in domestic and very light commercial areas. In ALL other circumstances please, please use a movement joint with metal side supports. They cost more but their performance is absolutely superior to plastic. Metal side supports transfer movement directly to the flexible infill. Plastic supports will bend or deform. Metal side supports provide good protection to tile edges against chipping, Plastic supports don’t!

The infill on plastic Movement Joints is prone to damage from impact and specifically from ladies high heeled shoes. The infill on metal based profiles is tougher and much less prone to this type of damage.